In recent years, the manufacturing industry has witnessed a remarkable transformation fueled by advancements in artificial intelligence (AI). Manufacturers are increasingly leveraging AI technologies to optimize processes, enhance efficiency, and improve product quality. Discover how AI is transforming the manufacturing industry as we explore its evolution from early automation to today's intelligent systems, which are revolutionizing production lines and reshaping the workforce landscape.

This blog post delves into the key innovations driving AI's impact in manufacturing today, highlighting the tools and techniques that empower manufacturers to stay competitive. Furthermore, we will take a forward-looking approach to examine how AI is poised to continuously evolve and redefine industry standards. Join us on this journey to uncover the profound changes AI brings to manufacturing, ensuring companies thrive in an era marked by rapid technological advancement.

Discover how AI is transforming the manufacturing industry: A historical perspective

The journey of AI in manufacturing began in the mid-20th century when pioneers first imagined machines that could mimic human intelligence. Early automation tools revolutionized production lines by increasing efficiency and reducing human error. As computer technology advanced, manufacturers started integrating more sophisticated algorithms, enabling machines to analyze and interpret data. This transition marked the beginning of a new era in manufacturing, where AI began to take on tasks that required cognitive capabilities, paving the way for an expansion in precision and productivity.

By the turn of the 21st century, AI had evolved from basic automation to complex systems that could learn and adapt. Companies like General Motors and Siemens began to pioneer the integration of machine learning and predictive analytics into their operations. This shift allowed manufacturers to optimize supply chains, improve quality control, and refine production processes. As businesses recognized the immense potential of AI, the focus shifted towards enhancing operational efficiency and competitiveness. The manufacturing industry was not just transforming; it was entering a new phase of innovation and growth, driven by the power of artificial intelligence.

Key innovations driving AI's impact in manufacturing today

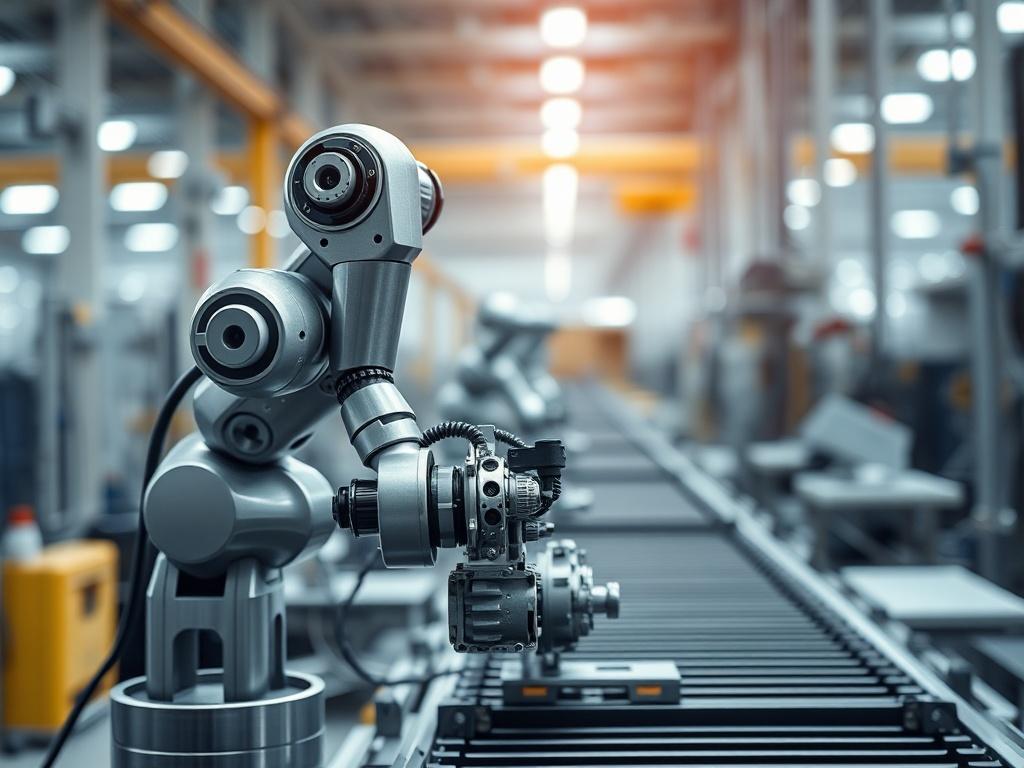

Artificial intelligence is redefining the manufacturing landscape through a series of groundbreaking innovations. Machine learning algorithms now enable manufacturers to analyze vast amounts of data in real-time, optimizing production processes and enhancing decision-making. Predictive maintenance, powered by AI, minimizes downtime by anticipating equipment failures before they occur, which significantly boosts operational efficiency. Additionally, robotics integrated with AI capabilities are transforming assembly lines, allowing for greater precision and speed in tasks ranging from welding to packaging. These advancements not only increase productivity but also reduce operational costs, making AI an essential component of modern manufacturing.

Furthermore, AI-driven supply chain management is revolutionizing how manufacturers approach logistics and inventory. By leveraging AI, companies can forecast demand more accurately, streamline inventory levels, and improve delivery times. This optimization reduces waste and ensures that products reach customers on time, enhancing overall satisfaction. Collaborative robots, or cobots, are gaining traction on the factory floor, working alongside human workers to enhance productivity and safety. As these innovations become more prevalent, it becomes clear that AI is not just a tool but a transformative force in reshaping how the manufacturing industry operates.

The future of manufacturing: How AI will continue to evolve and reshape the industry

As the manufacturing landscape continues to embrace AI technologies, we can expect to see even more profound changes in production processes. Innovations such as predictive maintenance and real-time data analytics will enhance operational efficiency, significantly reducing downtime and unexpected failures. Manufacturers will utilize AI-driven algorithms to optimize supply chain logistics, making it easier to forecast demand and adjust production schedules accordingly. This proactive approach will lead to increased agility in responding to market trends, allowing manufacturers to stay competitive in a rapidly evolving landscape.

Moreover, the integration of AI with emerging technologies, such as the Internet of Things (IoT) and robotics, will further revolutionize the industry. Smart factories will leverage interconnected devices to gather and analyze vast amounts of data, creating a seamless production ecosystem. This synergy between AI and IoT will enhance decision-making processes and promote sustainable practices, as companies seek to minimize waste and energy consumption. As AI continues to advance, its transformative impact on the manufacturing industry will lead to unparalleled levels of efficiency, quality, and innovation. Companies that adopt these technologies early on will set themselves apart in a future where smart manufacturing becomes the norm.